The BEST data.

Do what is right and not what is “always been done”

How it works - step by step

Define the proper physiologically relevant conditions for your clinical target or other application (such as 3D bioprinting)

Subject the specimen (biomaterial, tissue, injectable mateial, construct) to coherent stimuli, inducing respective fluid and nutrients transport closer to what is expected in the hostile environment

Assess changes in properties of the specimen in time, phase and stimulus domains, leading to the fundamental and invariant constitutive equation for given material, generating model-free data (no assumptions or artificial parameters)

Post-process experimental readouts with idempotent analysis (patented and patents pending), incorporating specimen history.

Extract invariant values, suitable for material behavior prediction, showing also the position and the direction of development of your material and provide solid data for its optimization.

Already tested? No problem.

When you already have data from previous experiments and if these conditions are relevant, BEST can extract the same or similar values from your data.

Please contact us for details as missing data and improper readouts may not be feasible for analysis

STILL UNSURE?

Please ask! Will be happy to discuss details. NDA is possible if data are too sensitive.

Key BEST features:

Shorten time and costs of materials development and optimization

Decrease/eliminate needs for extra animal testing

Characterize at coherent conditions, closer to physiological reality.

Eliminate assumptions on material linearity, homogeneity, material model

Enable high-output screening (instead of high-throughput screening)

Incorporate specimen history dependence and making prediction possible

Carry out a non-destructive evaluation in most cases - you may reprocess the specimen

Avoid usage of complex numbers or transforms - no troubles from harmonics or series expansion

Re-process retrospective data without need for new experiments

Incorporate drug transport signature (DTS) features when your material is a medicinal product or having CDR feature

BEST measures properties for the purpose - the same material may have different properties vs. conditions like media, temperature, etc., so it is important the values are exactly what you need for that medical application your material has its intended purpose.

Some BEST cases

-

New treatment of ceramic dental abutments for better aesthetics and improved mucosal adhesion, minimizing bacterial contamination risk.

OUTCOME: new abutments for clinical trials.

More: see BEST notes in recent publications (J. Periodontology and in MDPI Biomaterials) -

discovering new auto-mechano-induction (US Patent) effect in different cells development, proving ability to trigger changes in cells reaction to anticancer drugs.

OUTCOME: new special models for stem and cancer cell culturing under development. Recently tested for different viruses too (see publication in Materials) -

development of new scaffolds with proper biomechanic-fluidic properties polarization for better hyaline cartilage regeneration.

OUTCOME: new optimized scaffolds are being deployed in clinical practice.

See BEST notes for joints in the publication (Frontiers Bioeng. Biotech.) for details -

Revealed changes in new hyaluronic hydrogels with bioactive fillers affecting viscosity and stiffness, and how to manage injectability (US patent) and patient comfort.

OUTCOME: new hydrogels compositions in preparation. Bioprinting applications under development.

BEST Applications and Values

With the proper coherent testing and data analysis BEST generates in vitro evidence which

lowers the costs and time to get the correct data

provides outcomes as true real properties with better biofidelity and higher clinical/physiological relevance

enables model-free prediction of a specimen behavior and its unbiased comparison with the controls

with the high-output screening of lead solutions provides data for RAQA and regulatory compliance

raises ethical value of your biomedical product.

BEST data are needed for:

regulative compliance validation as with MDR 2017/745 (Annex I),

model-free prediction of behavior for specific clinical application,

lead development/lead optimization of the biomedical solutions,

new features discovery,

reduction, refinement and replacement ("3R") of animal testing (2010/63/EC).

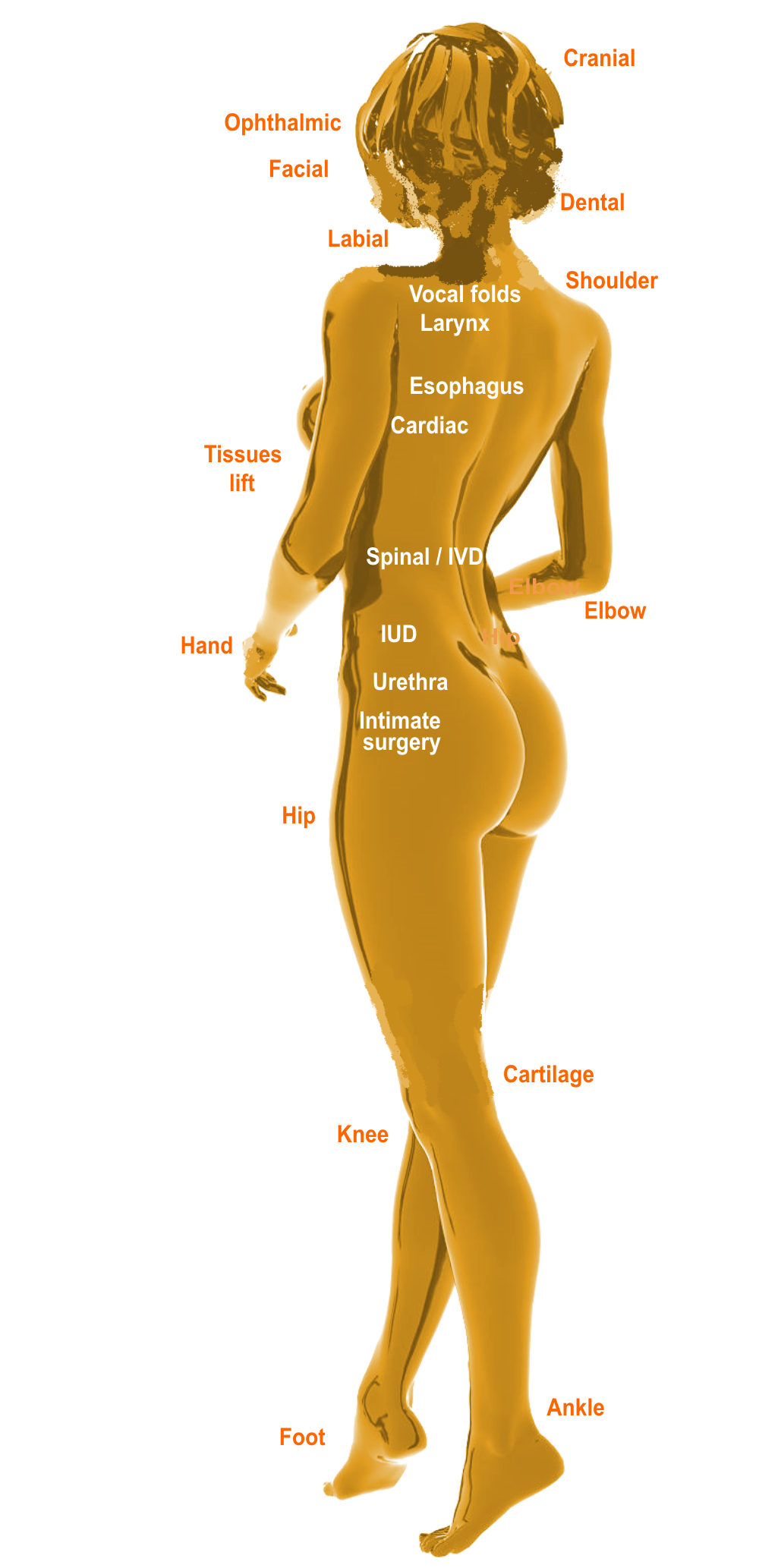

BEST applications span many medical targets, with a great variety of the functionality, optimization and risk assessment actions:

Tissues

Polymers

Hydrogels

Injectables

Decellurized

Bioceramics

Biometals

Phantoms

Composites

Hybrids

Drugs and CDR

. . . . .

Coherent testing

Idempotent analysis

Model-free data

Predictive outcomes

. . . . .

Clinical targets with BEST

3D bioprinting

ATMP solutions

Anti-bacterial

Bio-inks

Cancer

Cardiac

Cosmetic

Dental

Gynaecologic

Immunologic

Implants

Injectables

Joints repair

Neurologic

Ophthalmic

Orthobiology

Orthopaedic

Pharmaceutics

Plastic surgery

Pulmonologic

Scaffolds

Soft tissues

Spinal / IVD

Surgical

Urologic

Veterinary

Please inquire for customized solutions !